win53

Rover Rookie

real rookie but willing to learn with help

real rookie but willing to learn with help

Posts: 94

|

Post by win53 on Jul 26, 2015 10:58:16 GMT

Hi Could anyone help me please. My Facet Fuel pump has become very noisy like a machine gun. I have decided to replace it with a Bearmach 3.5 V8 Petrol External Pump. I purchased this from Transglobal Distribution for £28.95 the same one you get at JRW for £86. The problem I have is that no fitting instructions came with it and I notice there is only 1 lead to the pump. Has anybody fitted one recently and if so have you still got the fitting instruction for it. I have tried the web but can not find anything. I may be a little thick here but I am a novice to most people on here as I need help. I am sure my Facet Pump has two wires from it so I am a bit confused. Can anybody help please ? |

|

|

|

Post by petervdvelde on Jul 26, 2015 11:12:42 GMT

the wire needs to be connected to the + and the body of the pump will be the - connection and needs to be in contact with the "earth". If you use silentblocs for fitting the pump then you need to make a separate earth connection to the pump housing

Peter

|

|

win53

Rover Rookie

real rookie but willing to learn with help

real rookie but willing to learn with help

Posts: 94

|

Post by win53 on Jul 26, 2015 14:18:08 GMT

Thanks Peter that's helpful.

|

|

|

|

Post by lagain on Jul 26, 2015 18:07:44 GMT

I would suggest putting an inline filter infront of the inlet. One similar to what you have in the engine bay should be OK.

It could be muck has done in the Facet

|

|

|

|

Post by barryr on Jul 26, 2015 22:18:24 GMT

They come with an inlet filter I think. I bought the jrw kit before they did pics and overpaid for it imho. That said I am happy with it although I think it's noisy.

Mine is mounted on the x member where the fuel tap resides so I was able to fix and retain the reserve fuel supply.

As said here, the connection is for positive feed. I bought a facet rubber bobbin kit to mount it and that came with the earth lead to jump over the bobbins.

|

|

|

|

Post by petervdvelde on Jul 26, 2015 23:06:12 GMT

mine is fitted behind the cross member. I made a bracket so could use the cross member bolts and also used rubber bobbins  Peter |

|

|

|

Post by enigmas on Jul 27, 2015 8:10:59 GMT

Before you deep six the Facet pump, check that it's mounted below the tank, so that there is gravity feed to the inlet side of the pump and you may just find that it works OK.

These pumps are generally bullet proof and either work or don't. If it's noisy it's usually because the pump's drawing air or is mounted above by the fuel level in the tank.

|

|

win53

Rover Rookie

real rookie but willing to learn with help

real rookie but willing to learn with help

Posts: 94

|

Post by win53 on Jul 27, 2015 12:29:31 GMT

Hi Guys thanks very much for the info. My Facet pump is fitted in the engine bay on the side of the wheel arch. I take it this should be moved lower down then. I have already acquired the new pump so shall I fit this below the tank in a horizontal position as my Facet sits on the near side at an angle before the steering fluid reservoir and I was going to fit it there. Take it I will still have a problem if I do. If I cant will it be possible to fit it lower down on the side or should it be in another position entirely. Look forward to your advises guys. |

|

|

|

Post by enigmas on Jul 27, 2015 13:09:50 GMT

Just for fun wire your old facet up with a couple of jumper leads below the fuel level in the tank. I bet there's nothing wrong with it!

When you fit the new pump just mount it where it's convenient but lower than the fuel in the tank. As above. Good luck.

|

|

|

|

Post by johnwp5bcoupe on Jul 27, 2015 13:48:12 GMT

As Vince and Peter say the lower the better its a while since I fitted mine but I thought they didn't suggest you fitted the pump in the engine bay? where mine is I have like many other guys the option of the reserve  I removed the in line fuse the supply is fused on the standard block.   |

|

|

|

Post by barryr on Jul 27, 2015 19:29:09 GMT

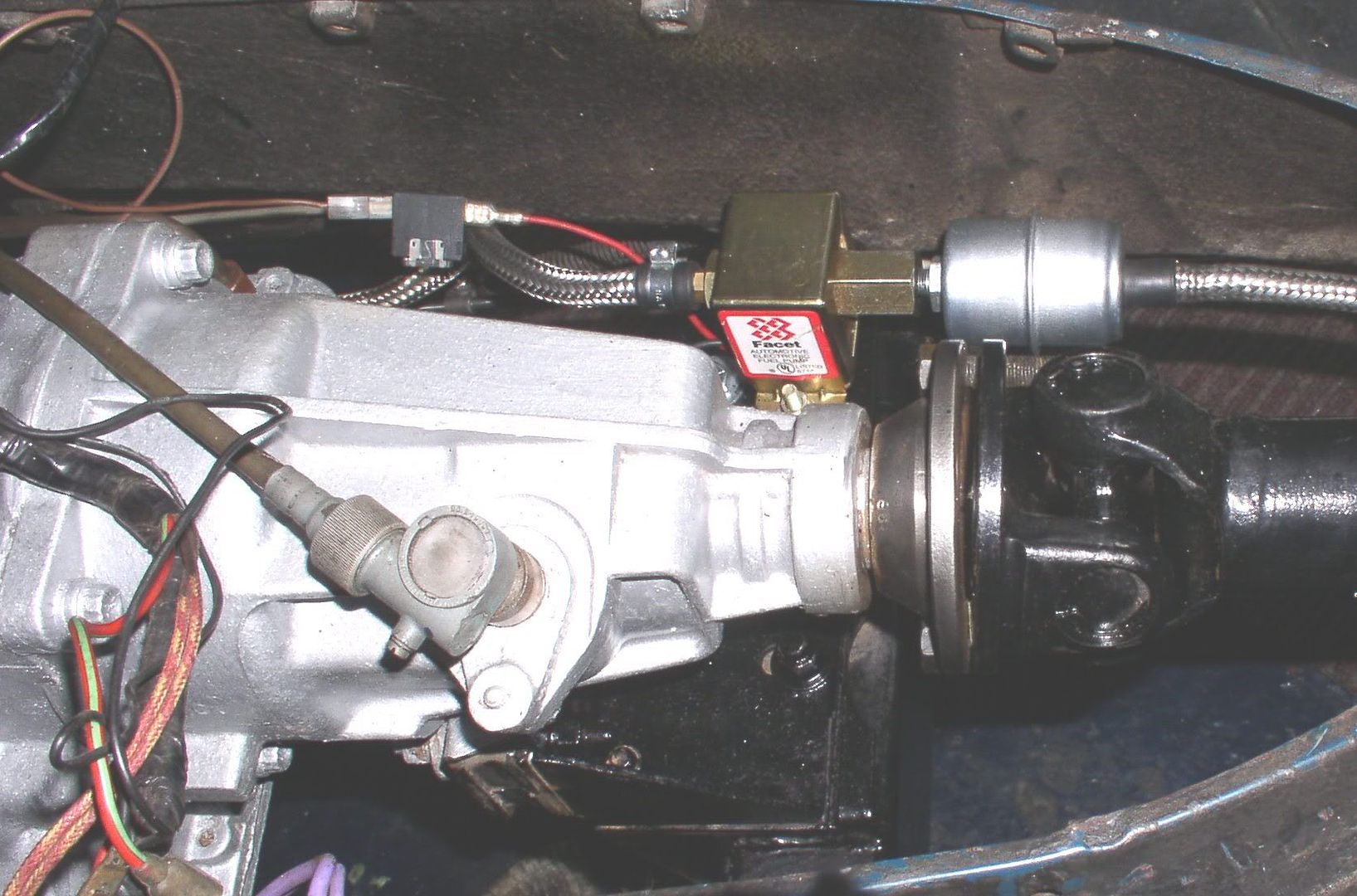

Interesting to see peters pump sideways compared to mine. I thought they had to be vertical!

I prefer peter's approach and may reconsider mine now!

|

|

|

|

Post by petervdvelde on Jul 27, 2015 23:14:24 GMT

Barrie,

I can't remember the instruction which came with the pump but i remember that i didn't fully follow the instructions so you could be right that my pump is not fitted at the correct angle. I choose this position as it is more or less protected by the cross member and the pump is hardly used as my car runs lets say 99% on LPG.

Peter

|

|

|

|

Post by johnwp5bcoupe on Jul 28, 2015 7:14:08 GMT

CUBE Type

Before You Begin…

Carefully read through these instructions before you pick up a tool. To prevent damage to your new fuel pump, install only after checking the proper voltage and polarity. The vehicle's polarity can be determined by checking to see which battery terminal has a heavy lead wire connected to the chassis. If the Positive terminal (+) is connected to the chassis, it is positive

ground. If the Negative terminal (-) is connected to the chassis, it is negative ground.

To reduce the possibility of vapor lock, do not mount the fuel pump in the engine compartment, near

the exhaust system, or any location that may exceed 140º F (65º C) ambient temperature. To ensure a good ground, mount the fuel pump on the vehicle frame whenever possible. The area of

the frame to be used should be thoroughly cleaned down to bare metal to obtain a good electrical connection.

If your vehicle is equipped with a fuel cut-off device, make sure you use that circuit to power the pump. Some vehicles use an oil pressure safety switch which will shut off the fuel pump if the engine stops with the key in the run position.

If you have anything other than a brand new gas tank in your vehicle, we strongly suggest that you fit

a fuel filter between the pump and the tank. Rust particles in the tank will, over time, damage the pump. Since many British Car owners have already fitted a filter, this may be a non-issue for you. We do stock an in line fuel filter (377-424) that will remove particles to 74 microns. It threads directly into the inlet side of the pump. If you want to pick up a filter locally, look for that specification.

The pump may make a tapping or clicking noise during operation. To dampen the noise, consider using rubber shock mounts when installing the fuel pump. Although some of our suppliers used to offer these mounts, none are available through Moss at this time. We have been told that generic rubber mounts are available from hardware/home improvement centres. If you do use rubber mounts

you must run a separate wire or strap to maintain your electrical connection from the pump body t vehicle frame.

The gas tank should be near empty. If it isn’t, a considerable amount of fuel may spill when the lines are disconnected from the fuel pump. We suggest that you drain the tank into a gas can, capping it and setting it aside for later.

You are working with gasoline and electricity. If you can do the work out side on a hard level surface, the fuel vapour will disperse. If you are going to do this in a garage, open the doors/windows and set up a fan to blow the fuel vapour outside. We suggest that you have a fire extinguisher (ABC rated) handy.

Jack the car up and support it securely with automotive jack stands on a solid level surface. Never work on a car supported by a jack.

Deciding Where to Mount the Pump select a location near the existing fuel lines and close to the fuel tank. If the original pump is near the tank, that is where this pump should go. Use the vehicle frame when possible. If another location is used, be sure you have a good electrical ground.

To avoid priming problems, do not mount the fuel pump more that 12" (30.48 cm) above the bottom level of the fuel tank. If the pump is even or below the bottom of the tank, it will be easier to prime. NOTE: It is recommended that the outlet of the pump

should be at least 45º above horizontal. This will allow any vapour build up to easily pass through the pump.

|

|

|

|

Post by barryr on Jul 28, 2015 22:38:59 GMT

No instructions came with mine - most of it is common sense but note even those don't say if the pump should be vertical or horizontal!

|

|

|

|

Post by barryr on Jul 28, 2015 22:41:16 GMT

Unless that bit about outlet being 45 degrees from horizontal at leat counts!

I guess that means mine is optimal being vertical?

|

|

|

|

Post by johnwp5bcoupe on Jul 29, 2015 5:26:22 GMT

Unless that bit about outlet being 45 degrees from horizontal at leat counts! I guess that means mine is optimal being vertical? Your type can be vertical or horizontal Barry the instructions were for the Cube type  |

|